We've detected you are outside the United States. Switch to our International site by clicking below

HDD Tooling Blog

Subscribe to RSS FeedMulti-duct Puller Pulls Through in High Stakes

Learn about the custom solutions engineered to address installing this much pipe in a maze of...

Horizontal Directional Drilling Guide For Rookies

This guide will help those new to HDD get up to speed, limit mistakes, and quickly become...

HDD Workforce Gaps & Rising Job Demand

The question that is glaring at every HDD contractor that is already struggling to find labor to do...

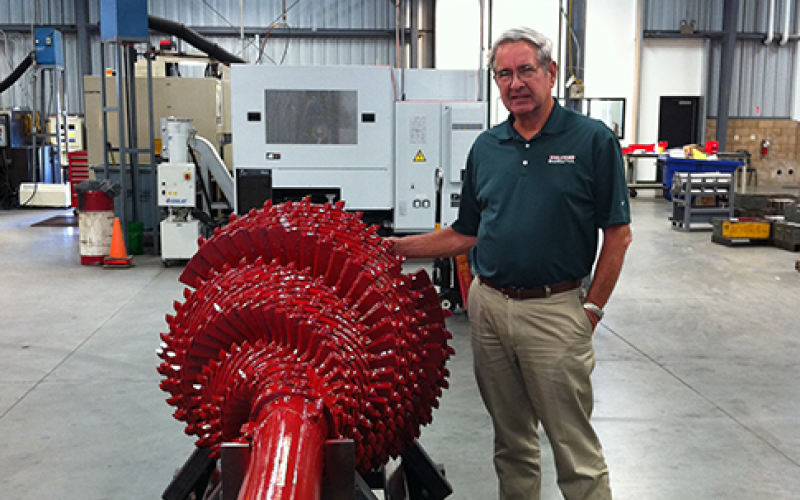

Melfred Borzall Marks 75 Years

“The biggest thing that’s changed [over the years] is people’s perception of the need for...

Effects of the Pandemic on HDD

Not all impacts of the 2020 COVID-19 pandemic have been negative. Here are three possible...

HDD Embraces eCommerce

Experts are talking about what has pushed the HDD industry from a technological-laggard into full...

HDD and the Environment

When you think of our industry and the environment, do you think of HDD's impact positively or...

Horizontal Directional Drilling: Cost of Downtime and How to Avoid It

Learn how to avoid downtime to lower your cost and increase your bottom line.