The fluted reamer that comes with your drill rig might seem like a great multi-purpose reamer. It’s sturdy, compact and hailed by OEMs as the perfect do-all reamer for a variety of conditions. It’s true, fluted reamers do have some benefits. But they are definitely not the do-all reamers they’re advertised as–especially if you’re looking to maximize production. Here are a few ways your fluted reamer might be slowing you down (along with a few tips on how to get your production back up to speed).

How Does a Fluted Reamer Slow You Down?

Fluted reamers generally provide insufficient mixing action, because it’s not what they’re designed for. This can be very problematic in combination soils like clay, where poor mixing can cause the material to ball up. When drilling in soft ground, if you don’t get completely stuck, pulling your reamer back through sticky material will be slow going. Insufficient mixing and pumping action will result in your reamer simply displacing the material in the hole, rather than actually slurrying the cuttings out. At the very least, you’ll have to do multiple passes through the same hole. Fluted reamers will also struggle in sandy conditions. The reamer will likely not mix enough drilling fluid with sand to help stabilize the hole and keep it open. Without the right mixing function, you risk collapse. Your hole is much more likely to cave in around the reamer itself or right behind your reamer, where you’re trying to pull product pipe. Finally, even though fluted reamers are designed with openings (flutes) to carry slurry out the back of the hole, the flutes generally aren’t deep enough to allow enough material to pass through. As a result, you’re essentially shoving lots of material forward that will slow you down significantly during pullback, and could even cause inadvertent returns.

Why Use a Fluted Reamer at All?

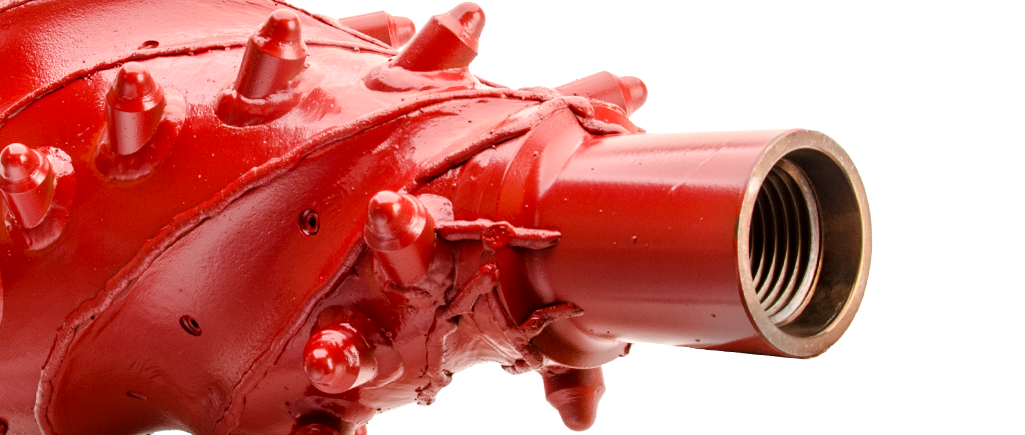

Fluted reamers do perform sufficiently under certain conditions. The low levels of mixing and pumping required for hard and abrasive soils such as shale or gravel make them best suited to drill this type of material. Most fluted reamers are also typically under a couple of feet long, which is pretty short. Because of this compact design, fluted reamers can perform well in tight areas. We resisted making fluted reamers for many years because we had proven other styles of the reamer to work much better. We finally gave in and developed the Juggernaut because the market demanded it. We figured that if HDD drillers are going to use a fluted reamer, we should provide one that will perform as well as possible. Unlike OEMs who manufacture rigs, non-HDD equipment and a slew of other products, HDD tools are all we do at Melfred Borzall. We spent dozens of hours adjusting our design to make sure that our fluted reamer could stand up to as many variables as possible. We added extra cutters and made sure that the flutes were deep enough to enable more slurry to pass. Then we conducted dozens of tests with drillers on actual HDD jobs in the field. We tracked pressures. We asked drillers for honest feedback about how the Juggernaut felt and if they could go faster or achieve higher rotational pressure. We used this real-world feedback to further refine our design.

Which Other HDD Tools Will Best Complement Your Fluted Reamer?

If you’re primarily using a fluted reamer for tight areas, we also recommend adding a couple of open blade reamers to your tool shed. Open blade reamers give you more mixing action when you need it and feature tapered cutters that gradually bore through the material. As always, your reamer choice depends on the material you’re in. For harder conditions, check out Shredder. For stickier conditions, a reamer like Terminator should be your go-to. You wouldn’t limit yourself to the drill bit that comes with a handheld drill. The same idea applies to your HDD tools. Always use a reamer designed for your specific conditions. It will speed your production and protect your tools and rigs in the long run. If you have questions about which reamer is right for your job, contact your Melfred Borzall distributor who can provide advice and suggestions about which tool will work best for you. Or talk to us directly over the phone or via our Live Chat feature.