We've detected you are outside the United States. Switch to our International site by clicking below

Our Story

75 Years of Groundbreaking Drilling Solutions

For three quarters of a century, we’ve kept our noses to the grindstone, developing HDD tools to make directional drilling more productive and more profitable. Our Southern California design and manufacturing plant is ground zero for the HDD tools that changed the way an entire industry drills. The way we do business sets us apart. Read below to learn more about who we are and how we continue to shape the future of horizontal directional drilling.

Three Generations in the Family

Not only has Melfred Borzall been the catalyst of the HDD industry movement for three-quarters of the past century, it has also been a legacy of three family generations. When Fred Melsheimer left his position in the oil fields to start his own company it would be handed down from father to son. Today that same family runs the company and are thriving with modern innovations and engineering to meet the needs of today's driller.

-

1946

Machinist, welder and innovator Fred Melsheimer launches Melfred Welding & Manufacturing, designing and creating tools for the first horizontal directional drilling system.

-

1955

Fred’s two sons, Ted and Dick Melsheimer start working after school at Melfred Welding & Manufacturing. Like their father, both are inventors and dreamers, developing hydraulic-powered drill rigs and designing the the DynaMole, a self-propelled boring machine that could bore and pull in 1500+ feet of gas pipe per day.

-

1972

Ted Melsheimer invents the successful line of Mustang pipe squeeze off tools.

-

1978

Fred’s son-in-law, Larry Coots, joins the company. As a talented mechanic and sales expert, he possesses the right blend of skills to get these tools into the right hands to lay the groundwork for a changing industry.

-

1981

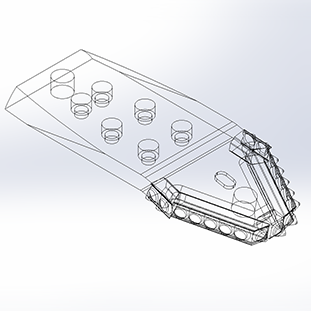

Dick Melsheimer launches Borzall Equipment, dedicated to designing and manufacturing drilling systems that could bore further while disturbing less ground. Borzall Equipment produces bits, reamers and other drill parts that last longer and stand up to tougher conditions and make drilling more productive than ever before.

-

1981

Borzall Equipment redesigns the DynaMole self-propelled boring machine for even better daily production of utility installations.

-

1988

Melfred Welding joins forces with Borzall Equipment to create Melfred Borzall, Inc.

-

1990

Melfred Borzall develops, demonstrates and sells the world’s first commercially available horizontal directional drilling system, the Sure Shot. Dick and other Melfred Borzall staff travel around the country, demonstrating this new technology and its tremendous possibilities for commercial drilling solutions.

-

1992

Melfred Borzall partners with first international distributor in the United Kingdom. This opens up opportunities for international expansion, ultimately resulting in Melfred Borzall distributors that span five continents.

-

1994

Melfred Borzall expands distributor networks throughout the United States to ensure that drillers can get the tools they need right away.

-

1996

Melfred Borzall focuses on creating and selling the signature long-lasting red tools that make every other HDD rig more productive.

-

2016

Melfred Borzall celebrates it’s 70th anniversary.

-

Today

Melfred Borzall’s mission remains unchanged: to enable a more efficient, cost effective means of installing utilities underground so utility contractors can be as productive and profitable as possible.

There's green behind our red tools

We don’t just protect drillers, we protect the Earth. Our Santa Maria plant houses 800 solar panels producing almost 150 kilowatts of power, enough solar electric energy to provide over 75% of the plant’s needs. We also cut our lighting energy usage in half by using skylights in offices & production spaces and replacing all our metal halide plant lighting with high-efficiency T5 fluorescent lights. We recently brought on two electric cars for business use which we recharge at the two plug-in stations in our north parking lot. When you see the “Made with Solar Power” label, not only are you getting a quality tool priced for value but you know that tool is made in a clean, high-tech environmentally friendly facility.

We’re proud members of the communities we serve. See all the ways we support emerging ideas and exciting opportunities for future generations.