Housing Selection Guide

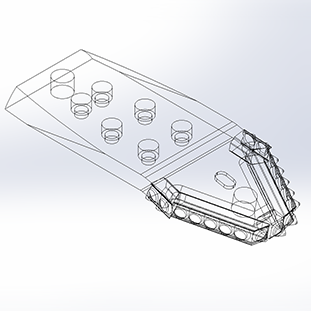

A Comprehensive Guide To Selection The Correct Transmitter For Your Jobsite Circumstances Such As Rig Thrust, Transmitter Model, & Other Important Factors.

We've detected you are outside the United States. Switch to our International site by clicking below

As directional drilling experts, we’ve got a lot to say about the industry. Our helpful and informative research in the industry can keep you efficient by staying up to date with new technologies, weighing in on industry challenges, and analyzing industry trends. All this to help you make smarter decisions for your drilling operation.

This illustrated guide will help those new to HDD get up to speed, limit mistakes, and quickly become the supervisors greatest asset on the crew. With so much growth in underground utility, a need for more onboarding and education to HDD operations & equipment is needed. This is it.

Use the tactics Navy Seals have refined to help you analyze and navigate your HDD operations in uncertain times. This article provides characteristics, examples, and approaches you can take to confront each VUCA category: volatility, uncertainty, complexity, and ambiguity.

With so many years in the HDD business, we’ve seen just about every mistake that can be made on a job site. In this e-book, we share the most common mistakes drillers make, give tips on how to avoid these mistakes, and provide tips on how to improve the efficiency of your next job. Let’s dig in.

We’ve put together this quick guide to share how you can make your HDD business function more smoothly, improve your productivity, and create lasting success. We’ve put together this quick guide to share how you can make your HDD business function more smoothly, improve your productivity, and create lasting success.

Moving the drilling industry forward by setting the standard for directional drilling tool manufacturers

Check out breaking press releases and watch informative videos to learn more about

Our goal is to be a catalyst for positive change within our community and beyond.