Like most good ideas, horizontal directional drilling did not spring forth fully formed. It took many years, and incremental developments in directional technologies, to get to where we are today. A lot of the HDD tools, methods and transmitter location systems we take for granted were based on technology created for different purposes, such as oil well drilling and general construction. So, to understand where we're going, it's vital to know how far our industry has come.

The Early Days of Horizontal Directional Drilling: The 1940s to 1960s

The true history of horizontal directional drilling began long before HDD itself. While HDD proper didn't emerge as a viable technology in construction until the 1970s, the seeds of innovation were sown well before that. Before that first job could occur, a number of technological advancements had to be made.

Melfred Begins

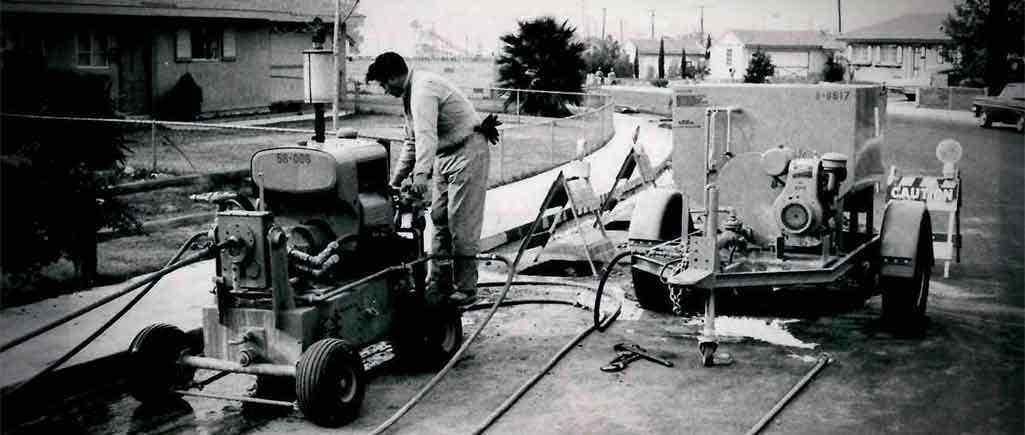

In 1946, Fred Melsheimer started Melfred Welding & Manufacturing. In addition to being a machinist and welder, Melsheimer designed and invented many tools and techniques that would form the basis for horizontal directional drilling. In particular, he pioneered the slurry, or "wet," boring process — the foundation of all modern-day HDD.

With much of the same spirit, Fred's sons, Ted and Dick Melsheimer, started working at the company in 1955, joining full-time in 1961. Together, they developed the DynaMole self-propelled hydraulic boring machine, which made longer bores possible. In 1969, Dick and Ted obtained a patent on the DynaMole. Part of that patent was the method of pulling a utility in behind a backreamer during horizontal drilling. Years later, because he had this claim as part of the patent, Dick was able to successfully stop a company from being able to charge a licensing fee to all contractors who used horizontal directional drilling. Ultimately, this saved the industry millions of dollars.

Enter Martin Cherrington

In the 1960s, another figure emerged who would be crucial to the birth of HDD. When Martin Cherrington watched a gas line installed using a handheld air drill, he got an idea for guided drilling. Eventually, this led to Cherrington custom building an early version of a directional drilling rig in 1964 to complete road boring jobs.

Formative Locating Technology

Additionally, there were several developments from the mid-1950s through the late-1960s that would form the basis for transmitter location systems. The technology used for sewer line tracking and cable locating systems provided these building blocks, which would be strengthened years later through the addition of transistors and microprocessors.

Breakthrough Years: The 1970s

In 1971, a huge breakthrough happened while Martin Cherrington was installing gas lines for the Pacific Gas & Electric Company (PG&E) — and they had to cross the Pajaro River in central California. Knowing he'd developed a new type of rig and was using some methods that were unconventional at the time, PG&E wanted him to try drilling underwater. It took some time, but the project was a success. In many ways, this opened the door for more projects and advancements. The construction industry saw this, along with Dick Melsheimer's numerous developments, as proof that horizontal directional drilling was a viable method of underground utility installation that caused minimal disruption to the surroundings.

The Development of the First Electronic Drill Bit Locator

In the late 70s, Dick Melsheimer, working with Goldac Co., introduced the first electronic drill bit locator. This locator served as a direct ancestor to modern-day walkover transmitter location systems, a core component of horizontal directional drilling equipment. While this technology, as well as Cherrington's contributions, still wouldn't be commonplace for quite some time, they were key stepping stones toward a thriving HDD industry.

The Modernization of Horizontal Directional Drilling Equipment: The 1980s

The breakthroughs of the 70s led directly into the major technological developments of horizontal directional drilling equipment in the 1980s — and that ball hasn't stopped rolling. In 1981, Dick Melsheimer started a new company called Borzall Equipment to focus on producing long-lasting reamers, bits and other HDD tools. Later in the decade, he would join back up with Melfred Welding to form Melfred Borzall.

Technology Takes a Leap

The late 80s saw significant leaps in magnetic steering technology, marking a turning point for the industry. In 1988, Radiodetection, a UK utilities testing equipment company, produced the first radio transmitter (also called a sonde). The addition of sondes to directional drilling rigs would mean that drillers could know the orientation of the steer face on their bits, as well as the location and depth, allowing them to guide the bore fully.

Modern HDD Rigs

And with that, HDD really started taking off. Also in the late 1980s, a company called FlowMole produced the first true HDD rig of the modern era but did not make it commercially available. Instead, they sold their HDD services for installing utilities.

Around 1989, Dick Melsheimer and the crew at Melfred Borzall began developing the first horizontal directional drilling rig that would be sold commercially: The Sure Shot Directional Drilling System.

It All Comes Together: The 1990s to 2000s

The introduction of the Sure Shot in 1990 opened the HDD floodgates. It was available to contractors and drillers everywhere and introduced several revolutionary features, such as an electric strike alarm and electric over hydraulic control valves for improved control, visibility and safety. Melfred Borzall demoed the Sure Shot around the U.S. and even sold one in New Zealand in 1991, which was used to complete the first directionally drilled river crossing. Horizontal directional drilling was now a global phenomenon in the construction industry.

The Arrival of the DigiTrak Transmitter Location System

In 1991, another major milestone happened in regards to walkover tracking systems. Digital Control introduced the DigiTrak system, designed from the ground up to locate boring tools (rather than cables as had been the standard). The DigiTrak quickly became a crucial piece of horizontal directional drilling equipment, giving drill rig operators roll, pitch and more accurate location and depth readings — and at deeper depths. The DigiTrak transmitter location system also introduced a remote display, allowing the operator to see what the locator saw.

The Rise of the Internet — And New Markets for HDD

As popularity and demand for the internet rose in the mid-90s, so did the need for fiber optic cable installations. This proved to be a massive market for HDD. By the year 2000, nearly half of underground jobs were completed using horizontal directional drilling equipment — mostly due to demand from telecommunications companies. However, this boom happened quickly and started to fizzle out. It evened out eventually, though, and most experts speculate that the HDD industry will see steady demand from the fiber optic and telecom markets for the foreseeable future.

Horizontal Directional Drilling in the Here And Now

Over the years, HDD tools have become more and more sophisticated to handle larger and larger jobs. The technology is more wide-reaching and effective, giving drillers more control. Because twenty-first century advances in HDD equipment have made the process more user-friendly, drilling has become a viable career option for many people. The work of all of those who contributed to the development of HDD has paid off big time — it is now a proven method that offers a cost-effective solution to construction problems. Since the process doesn't disturb natural beauties on the ground's surface, many people have also recognized its unique environmental benefits, which secures HDD's place in the future of construction and utility installation.

Step Into The Future with Melfred Borzall

We're proud of our place in HDD history, but we have our eyes planted on the future. We craft all of our horizontal directional drilling tools with the same pioneering spirit we've had since the beginning, and we've made it our mission to get our customers the parts they need faster and more efficiently. Whether it be the FastBack system or the Pit Bull design, we're constantly innovating to find the most efficient and productive means of installing utilities underground. So, take a leap forward with us — we've got a pretty good idea of where things are headed.