Choosing the appropriate housing starts with understanding your site and job conditions. Factors like ground type, terrain, drilling depth, and utility presence play a significant role. It’s also crucial to determine whether you need versatile housing for various bits and transmitters or a specialized option for a specific task. Consider your current tooling and equipment setup to ensure compatibility. For example, investing in a 3-¼” housing with direct pullback features, even if unused initially, can save costs down the line. Always align your choice with your drill rig’s thrust rating to avoid equipment damage and inefficiencies.

Two Questions To Ask When Selecting A Transmitter Housing

There are different types of locating, including wireline and gyro-based locating - but our focus for this article is solely on walk-over locating in HDD applications. There are different types of transmitters for various applications, but we’ll refer you to this article about transmitter types if you are looking to dive deep into that. Now, let’s dig into what questions you should be asking yourself.

1. What are my site & job conditions?

Ground type and terrain. How deep will I be drilling? Is there an existing utility where I’m drilling? What is the maximum diameter I need the pilot hole to be? Do I need something versatile that can be used with several bits or transmitters or specialized for a specific job? What sort of pullback is optimal for my ground and job conditions?

2. What is my current tooling & equipment setup, and what compatibility do I need?

Suppose you are purchasing a new full setup (housing, locating system, and tooling). In that case, it is much easier to ensure everything is compatible than replacing only one worn-out part of a complete setup. If this is you, then you should be thinking about future-proofing your tooling purchases to the greatest extent possible. For example, suppose you are purchasing a 3-¼” housing for a current setup that you know will stay regional in the same ground type. In that case, you will likely want to ask yourself if direct pullback will ever be a consideration or possibility in the future. If so, you’ll want to look at purchasing a transmitter housing that comes already equipped with those features, even if you aren’t using them right away. The alternative may cost you double when that could have been thought through at the time of investment.

Transmitter Housing Types

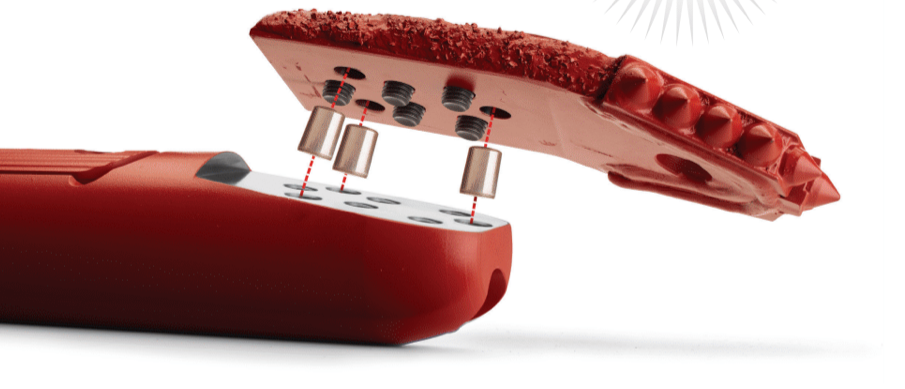

These housings allow transmitters to be loaded through a side cavity, enabling quick loading and unloading without dismantling the drill string.

Bolt-on Housings

Ideal for versatile applications, bolt-on housings work well in variable ground types like sand, cobble, or hardpan. They’re best for pilot bores under 7” in diameter and offer direct pullback options for small to mid-sized projects.

When drilling with a bit that is bolted to the housing, there is a particular rotational force that puts some wear on the blade. It can also put extra strain on the bolts holding the blade to the housing and risk shearing those bolts if the rotational force extends beyond the bolt's shear load capacity. Melfred Borzall has a patent-pending innovation, the Pit Bull Design, that increases the blade bolt’s shear load capacity, but if your pilot bore needs to be too large, you may find a blade is insufficient. For pilot bores, under 6-½ to 7” is the sweet spot for blades. Barring uncommon specialty blades, you may want to think about opting for a thread-on housing + bit option if it is larger and the soil type is too compact.

Thread-on Housings

These are better suited for tougher ground conditions where higher RPMs and rotational forces are needed. They also provide greater flexibility, such as universal compatibility with major transmitter models and conversion options for bolt-on configurations. One thing to keep in mind when selecting a housing is that there are options available for the side-load, thread-on housings that are not typically found in a bolt-on option that may give you more flexibility. For example, Melfred Borzall offers a “Universal” Side-load, Thread-on Housing that allows you to use most major transmitter models or 15-19” size transmitters.

So, suppose your company has crews across the nation and is using various transmitter types. In that case, you have the option to use a single housing with any DCI®, Underground Magentics®, or SubSite™ transmitters (not 8” transmitters). Another option that makes a thread-on housing more flexible is bit body attachments that convert your thread-on housing into a bolt-on housing. These are essentially bits that resemble the nose of a bolt-on housing with fluid nozzles (and Pit Bull™ pins if Melfred Borzall). With this, you can continue to use your blades if you run into the ground that calls for it without having to purchase another housing.

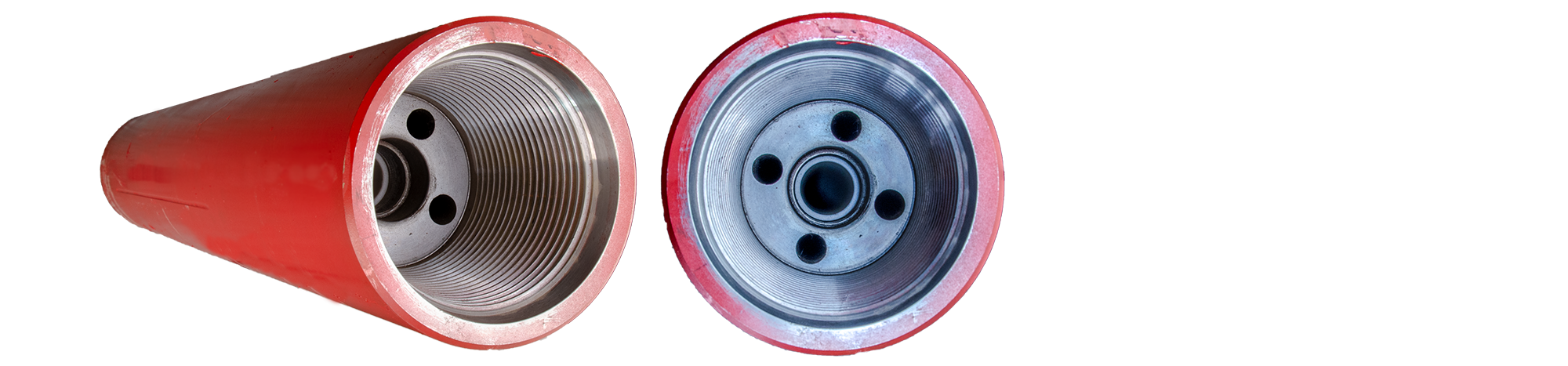

End-Load Housings

End-load housings are designed for high-flow fluid capacity and cable transmitters. They are ideal for specialized applications like mud motor systems, which require large fluid volumes to power drill bits in challenging rock conditions. Even though the quality and strength of side-load housings have made significant advancements over the years, one thing is not changeable–the space that a transmitter cavity takes up in the side of the housing. Because there is a cavity machined into the side of the housing, the gun-drilled fluid passage holes must be limited in number and arranged so they do not interfere with the transmitter cavity. In a standard setup, the given number of fluid holes is plenty to keep your transmitter cooled. The proper amount of fluid is flowing to the end for cutting action and proper slurry mixing downhole (if you adhere to manufacturer specs for fluid & pressure). But when you get into something other than a “standard” setup, such as a mud motor that runs a tri-con roller bit, you’ll need a higher flow of fluid to get to that bit. Enter the High Flow End-load Housing. Since the transmitter is inserted through the end into the center, there is no need for a separate sonde cavity. That means there is room to insert added fluid holes and for a higher flow rate of fluid. If you are running a mud motor, you will undoubtedly need high-flow housing.

DRILLING SYSTEMS

Mud Motor System

In most drilling operations, the drilling fluid (often referred to as mud) used for directional drilling aids in the cutting, cooling, and flowing out cuttings. But with a mud motor, the pressure and flow of the fluid actually powers the drill bit to spin and cut. Yet, a mud motor utilizes this fluid in flow pressure to rotate the drill bit. This shifts the power source from the rig's hydraulic motor to the fluid itself. The entire system is made up of some key components:

-

Mud motor—The “motor” part is an enclosed shaft with rotor and stator components. It uses the drilling fluid's pressure and flow to generate torque and rotation speed. The shaft is slightly bent to enable steering.

-

High-flow, end-load housing - This is to protect the transmitter and enable the enormous amount of fluid that will need to get to the end.

-

Drilling fluid - LOTS & LOTS of it. Typically, reclaimers/recyclers are used to separate the mud and reuse the fluid.

-

Specialized bit - Tri-cone roller or PDC bits are popular when encountering conditions like hard rock.

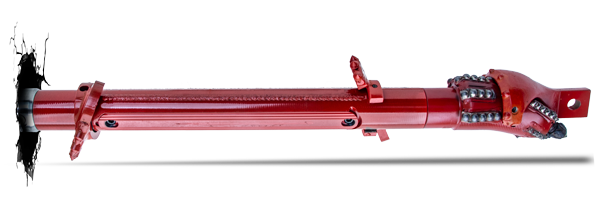

Direct Pullback System

Taking a step back from the intense rock drilling scenario we just described, let’s look at a system that really focuses on jobsite productivity on jobs that are not as big and hairy as drilling through hard shale or limestone. When your profitability is dependent on your day’s high productivity, breaking out tooling and reconnecting can be a serious time (and money) drain. Some systems leverage your already-mated pilot shot tooling for the pullback as well. This means that you don’t have to jump in the pit, break out a connection, reattach a reamer and swivel, and then pull back. With direct pullback systems, the pilot shot tooling is transformed into your pullback tooling without having to remove the drill head. There are several components to this that we have already nodded to earlier in this article, but here is a direct pullback system laid out:

-

Direct pullback compatible transmitter housing (either side-load, bolt-on, or side-load, thread-on is usable) - These housings usually will have an integrated fluid port in the tail and some flats with bolt holes to attach pullback cutters.

-

Directional blade or thread-on bit (depending on housing choice) - the bit/blade is an important component because this will determine what type of pullback device you will use.

-

Pullback device - the device that attaches to the bit or blade and puller or swivel pulling the product

-

Cutter Blocks - Attachments designed specifically for the transmitter housing that are staged up in size from front to back and widen the hole during pullback, transforming your housing into a reamer.

-

Extra Fluid Flow - integrated ports and added adapters with extra fluid ports are necessary because the flow from the small housing nozzles is not enough if you are reaming the hole, and the material needs to be carried out of the hole through the drill fluid flow.

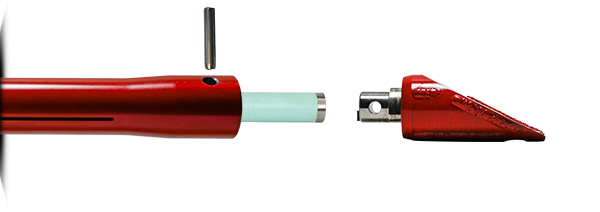

Service Shot System

Service line installations are typically very small-diameter service line installations in residential areas, such as gas lines coming off the main line from the street to the house. They are short, shallow bores, and contractors have to get multiple shots in a day to be profitable. A service shot system was designed to safely and efficiently expedite these scenarios that often involve other complexities, such as tight setup areas and congested mazes of existing (and sometimes unmarked) underground utilities. The components of a service shot system are:

-

End-load Housing with Threadless Bit Attachment - This HDD transmitter housing securely connects and quickly disconnects from a direct-connect bit and operates with an option for limited fluid use to expedite cleanup.

-

Threadless Bit - A bit with a highly tapered steer face for quick steering and hardfacing protection, but no teeth or chunky carbides that may risk catching on other existing utilities.

-

Threadless Reamer - The reamer also holds no real teeth for cutting to protect from snagging other utilities. Still, it enables a direct pullback option with threading in a pulling eye to attach to the product.

-

Threadless Pulling Eye - If no reamer is needed, you will want to use the direct-connect pulling eye to attach a swivel or shackle to the puller with the product.

IN SUMMARY...

Whether it's soft soils, clay, cobbles, or challenging terrains, Melfred Borzall offers specialized transmitter housing solutions tailored to meet the diverse needs of your HDD projects. By leveraging the expertise and quality provided by a manufacturer like Melfred Borzall, drillers can ensure optimal performance, reduce downtime, and achieve successful outcomes.

As the field of HDD continues to advance, staying updated with the latest tools, techniques, and industry best practices is crucial. Our experts are happy to speak with you and help you make the best choice according to your site-specific factors, budget, and environmental considerations. There is a reason Melfred Borzall has remained one of the most trusted names in HDD manufacturing, and we are here to help you succeed in our fast-paced and demanding HDD industry.

*Only Melfred Borzall Transmitter Housings are represented here. We do not make claims on compatibility with any other manufacturers’ transmitter housings and recommend you consult a manufacturer for a specific make and model before drilling.